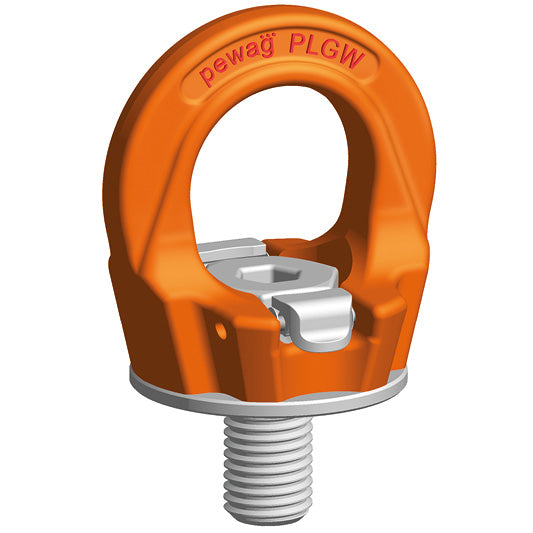

Pewag Profilift Gamma Lifting Point (PLGW)

The PLGW lifting point has been developed and manufactured according to the very latest standards.

This lifting point can be very simply tightened by hand and then aligned in the load direction – a system that is ideally suited for frequent assembly / disassembly applications. However, if the lifting point is to be utilised in a more permanent application and / or is subject to vibrations during use, the torque settings in the load table must be observed.

This patented system has proven itself from the beginning and promises unsurpassed ease of use.

The eyebolt is 360° rotatable, comes with an interchangeable special screw that is 100% crack tested and finished with a chrome VI free corrosion protection.

Each lifting point is marked with an individual serial number, the load capacity and the thread size. A batch number is also displayed on all load bearing parts such as the eye and screw. All of these factors make identification and traceability for mandatory regular inspections easier than ever.

The PLGW 'Supreme' range is available with metric or UNC thread options and can also be supplied with long (max.) or custom bolt lengths in metric form which are supplied with a special 100% crack detected prevailing torque type locking nut and washer to DIN 980-V (PLMS).

Also available with peTAG upon request.

Metric thread sizes available: M8, M10, M12, M16, M20, M24, M30, M36, M42, M48.

UNC thread sizes available (Supreme version only): 3/8", 1/2", 5/8", 3/4", 1", 1 1/4", 1 1/2", 1 3/4".

PLGW 'Supreme': tool-free assembly and disassembly

Latch in position 1: Latch is not in contact with the screw head.

• The latch is held open with a patented spring.

• The eyebolt is rotatable.

Latch in position 2: Latch is in contact with the screw head.

• The latch is held in place with a patented spring.• The eyebolt is not rotatable, i.e. the fastening torque is transmitted to the screw and thus the eyebolt can be mounted and removed.

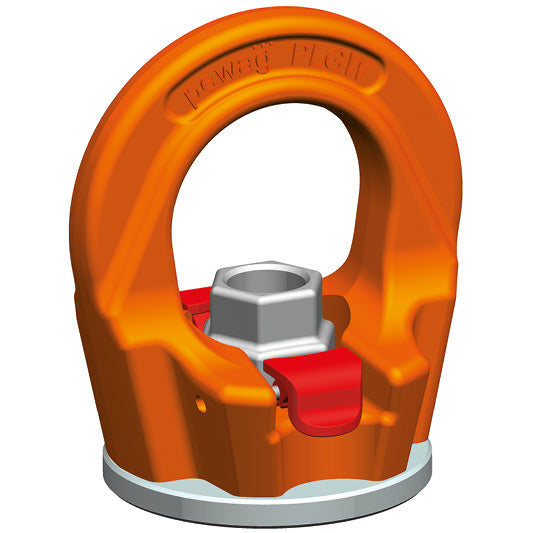

PLGW basic:

PLGW basic:

A simplified alternative to the Pewag Winner Profilift Gamma PLGW 'Supreme' is the PLGW 'Basic'. Offering the same benefits as the Pewag PLGW Supreme in terms of measurement, load capacity and application, the Pewag PLGW basic differs only when it comes to assembly.

This lifting point can be mounted hand tight using a standard Allen key then aligned in the load direction. However, if the lifting point is to be utilised in a more permanent application the torque settings in the load table must be observed.

For lifting point sizes M8-M20,

use the special Allen key sold

seperately.

Permitted usage

For load capacities in the permitted directions of pull, please refer to the load capacity table. Adjust the lifting point in the permitted load direction before loading.

• Loadable with a 4-fold safety factor under break in all directions

Non-permitted usage During assembly, ensure that improper loading cannot arise due to any of the following factors:

During assembly, ensure that improper loading cannot arise due to any of the following factors:

• Direction of pull is obstructed

• Direction of pull is not within the indicated area

• Loading ring rests against edges or loads

• Assembly with additional tools (e.g. extension) is not permitted

The load ring must be placed in the direction of pull before loading – do not turn under load!

For additional details and information, please refer to the full operating manual.

Calculating the required thread length (L):

Calculating the required thread length (L):

L = H + S + K + X

H = Material height

S = Thickness of the washer

K = Height of the nut (depending on the thread size of the screw)

X = Excess length of the screw (twofold pitch of the screw)

L max. = n max.

In addition to the standard and maximum thread lengths, Pewag also offers cut-to-length thread lengths.

Customised and maximum thread lengths are supplied with a washer and a crack-tested, corrosion-proofed screw nut.

Each lifting point comes with an individual serial number.

For detailed information such as method of lifting, number of legs, angle of inclination etc., please refer to the tables with the technical data.